KITCHEN EXTRACT CLEANING CASE STUDY JUNE 2016

Overview

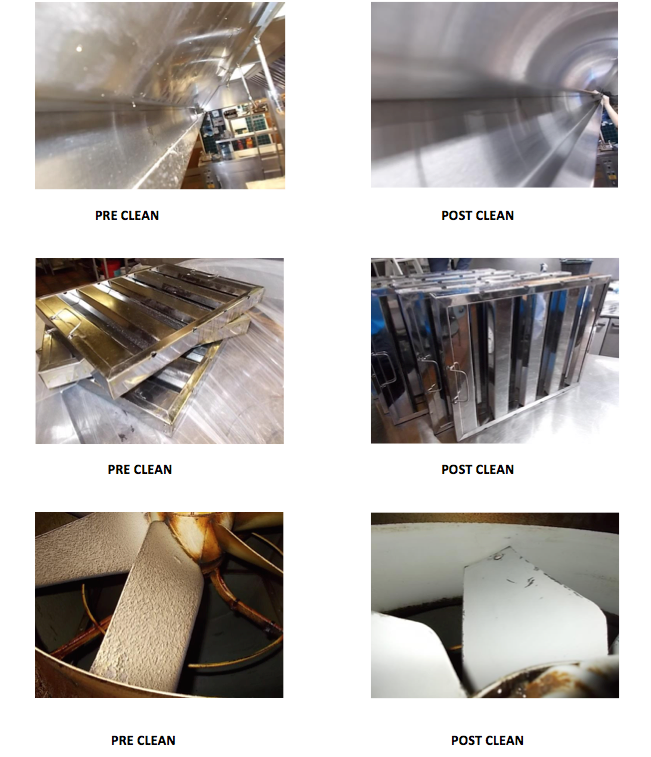

Job Type: Commercial Kitchen Extract Cleaning.

Site details: Main kitchen for prestige venue in Kent, catering for over 200 covers per day.

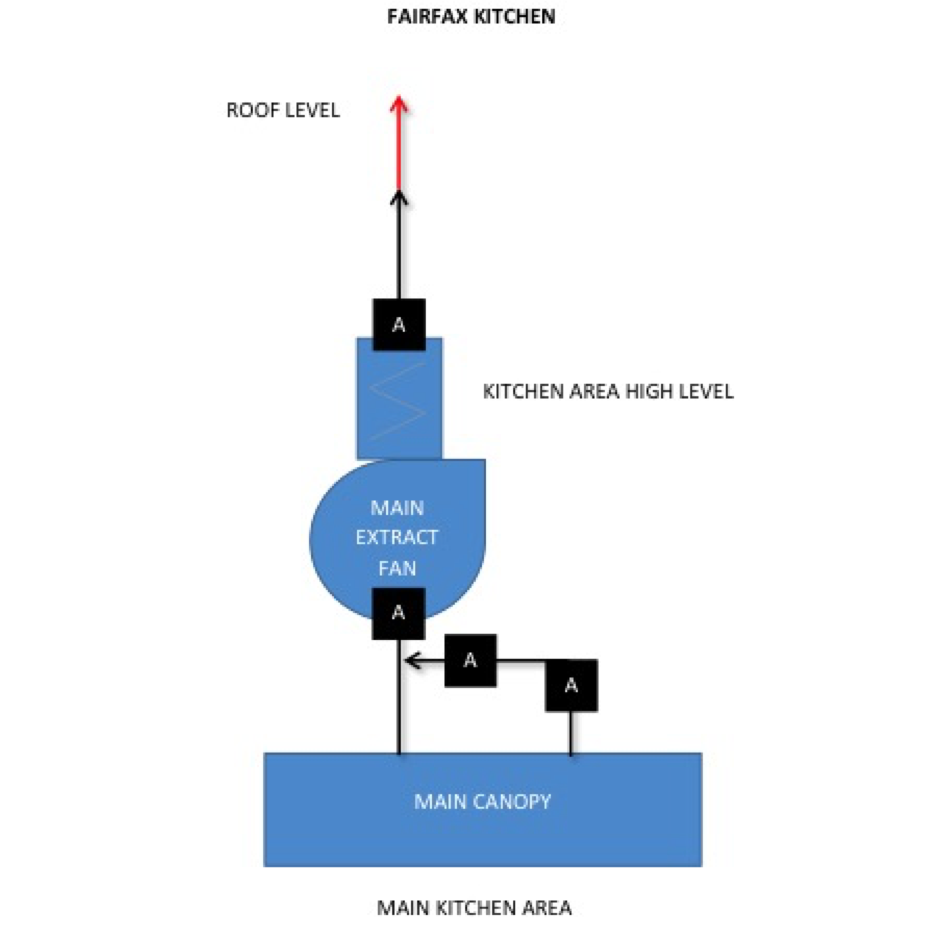

Special features: System comprises of one canopy hood (4.5 x 2.5 x 1)m2 with approximately 9 metres of extract ductwork.

The system operates under high grease load and temperature. Due to the varying types of cooking, this system is cleaned on a 6 monthly basis.

Observations

- Kitchen Extract Systems have an increased fire, odour, vermin & hygiene risk compared to general supply and extract systems. This is due to the grease build up acting as a potential ignition source, contributed by the heat in the kitchen, possibly elevated oxygen levels from a fresh air supply source and the general deposition of cooking oils on ventilation system components and the ductwork itself acting as fuel.

- Wet Film Thickness Tests (WFTT) were carried out at various locations throughout the system, to determine the overall level of grease deposition. Individual readings of over 50 microns are deemed unclean. An average reading across the system of 200 microns or more is deemed unclean. Any individual readings in excess of 500 microns require immediate attention. In accordance with BESA TR19, tests were carried out at the following locations (where accessible).

- The WFTT readings pre clean were as follows: Canopy 500 microns, ductwork from canopy 600 microns, fan unit 700 microns, ductwork after fan unit 600 microns.

- The work was carried out successfully by degreasing and deep cleaning the canopy, grease filters and the internal surfaces of the associated ductwork.

- All areas were properly cleaned with results below 50 microns.

- No faults or recommendations other than continued cleaning at the recommended intervals.