We got VIP treatment as a local business – all queries were answered professionally and the work itself was fast and clean – no mess left on site. A refreshing attitude! Thanks to the team!

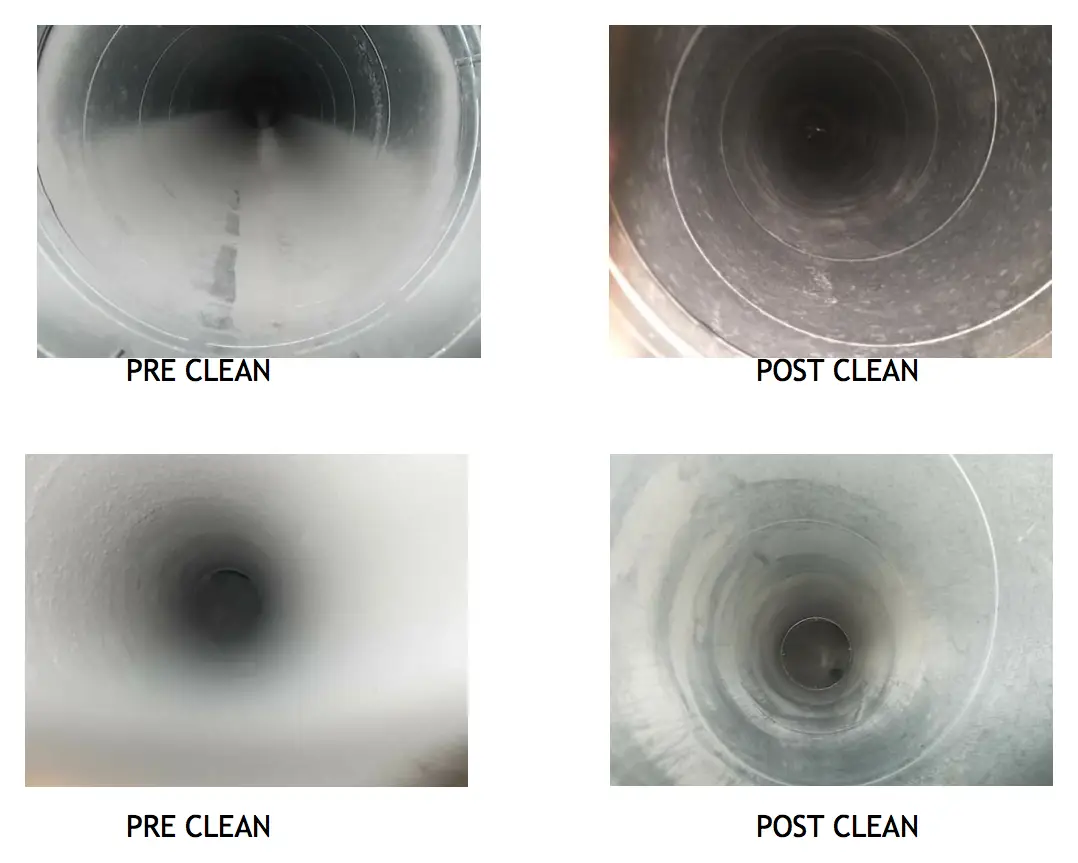

Job Type: Commercial Supply & Extract Ventilation System Cleaning.

Site Details: One of the UK’s largest manufacturers of aircrete blocks and systems.

Special features: 5 Ventilation systems.