Looking for companies for the cleaning and servicing of my kitchen canopy and ducts I found, via Google, overpriced local traders. I am so glad I looked on the BESA website and came across Clean Air Ltd. The lads you sent round were polite and did a good job. I was so confident in your pricing and work I recommended Clean Air to my church for their kitchen work. God Bless you all.

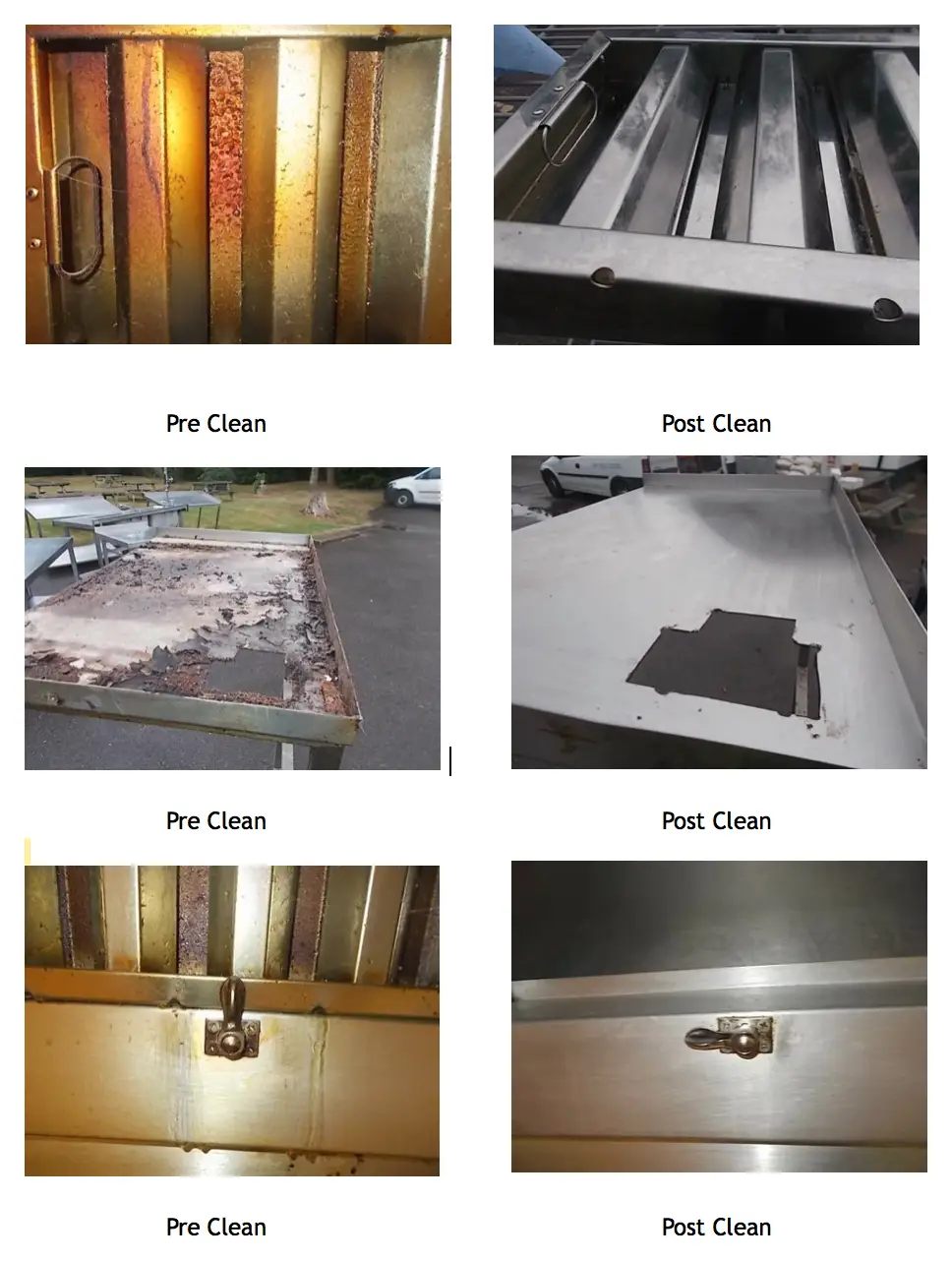

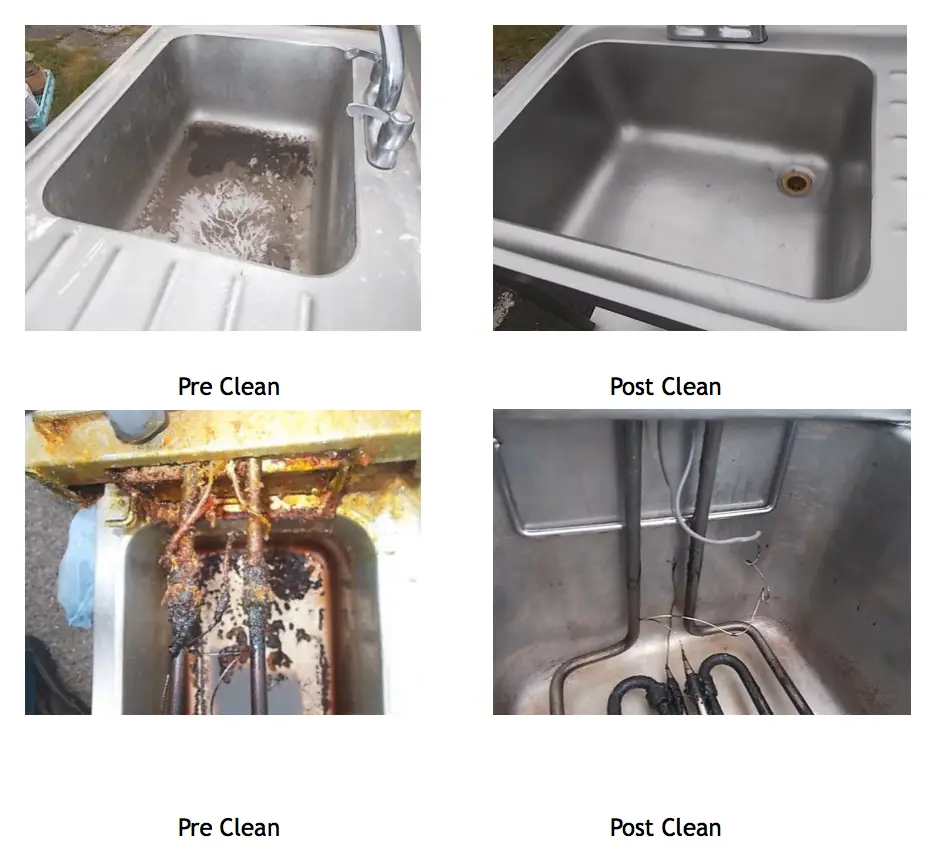

Job Type: Commercial Kitchen Extract Hood Cleaning & Deep Clean following a flood within the premises.

Site details: Popular Village gastro pub.

Special features: System comprises of one canopy hood (3 x 0.5 x 1)m2 with baffle filters and a main extract fan

The system operates under high grease load and temperature. Due to the varying types of cooking, this system is cleaned on a 6 monthly basis.